Many types of drilling equipment are used to get through hard surfaces. In fact, two common methods employ pneumatics and hydraulics. So which is the best one, pneumatic or hydraulic rock drill methods? Let’s take a look at each process to help you make an informed decision.

Pneumatics

Pneumatics works with compressed air. For example, when you go to the drive-through window at your local bank, you place your deposit or withdrawal papers in a tube, set it into a little chamber and push a button. Within a short amount of time, the tube shoots through an air tight tunnel to the bank clerk, thanks to the power of suction. This is basically how pneumatics works.

Hydraulics

Hydraulic equipment works on the power of compressed fluid. Here is an example. When you step on the brake pedal in your car, it pushes a rod which moves pistons in the master cylinder and this forces fluid to the brake calipers, causing them to close the brake pads on the rotors, which are attached to the car’s wheels. This increased friction stops the wheels from turning.

Which is More Powerful?

Both compressed air and fluid contain a great deal of energy and it depends on the application, which is best.

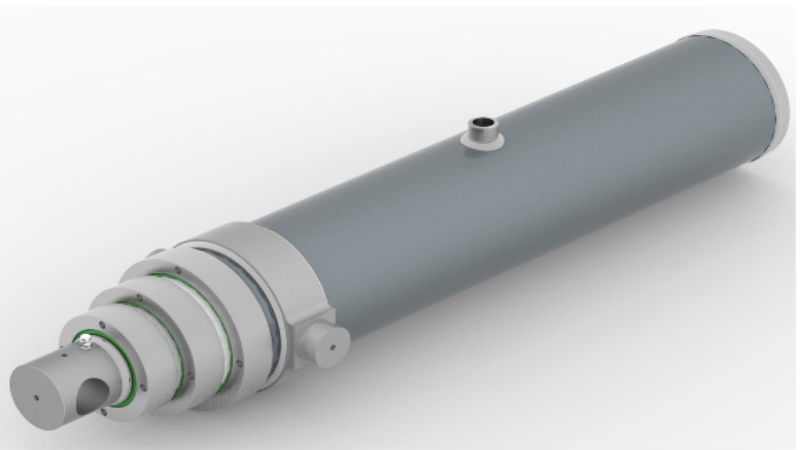

How Does This Relate to Pneumatic and Hydraulic Rock Drill Equipment?

When you look at overall efficiency of each system, hydraulics wins with 30 percent to 10 percent for pneumatics. This means, if you want the most power and energy efficiency for your money, a drilling system which relies on the power of fluid may be the best choice.

In addition, drilling with hydraulics can be done with considerable more pressure than with pneumatics.

Noise Levels

In today’s work environments, noise pollution can be a major issue. Pneumatic drilling is usually noisier because it creates noise in three different ways.

* Sounds from drilling mechanics

* Sounds from the process of drilling

* Air escaping or exhausting from the drilling mechanism

The Value of Compression

Both systems work on compression, however, fluid cannot be compressed but air can. Hydraulics makes it easier for components to be held in one place without the need for additional equipment.

Distance

Hydraulic fluid cannot be transferred for long distances, without a great deal of cost. The components must all be part of one system. However, this is not true with air pressure.

Conclusion

Most professionals believe the hydraulic rock drill has significant advantages over the pneumatic type drill. Although there are some disadvantages, they should not be too difficult to overcome with the right engineering and equipment.