One of the most important steps in brewing beer is carbonation. Consistent carbonation is critical to shelf life, taste and beer consistency.

Many new craft brewers carbonate by hand, using either the “hand pressure and time” technique, or hand pressure and shaking the keg. These methods are fine when you’re making home brew, but become difficult or impossible when you begin brewing in larger batches.

In addition to hand carbonation being extremely difficult when you brew in large batches, it’s almost impossible to make each batch consistent when carbonating this way. As your business grows, and you gain more customers, consistency of flavor and texture is critical to customer satisfaction. Those customers were hard earned; don’t lose them because your beer flavor is inconsistent.

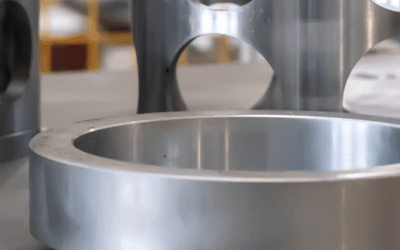

A professional beverage carbonator makes short work of carbonating your brews. It speeds up and automates the process for you. But, even more importantly, it ensures every batch is perfectly carbonated. This means you need never worry about shelf life, flavor or consistent batches of beer.

Talk with your equipment vendor about installing a beverage carbonator into your brewery process. They can incorporate the carbonator into your existing process or create an entirely new brewing process that is more automated and allows you to brew more beer at once.

As demand for your product grows, your equipment vendor is a valuable partner in helping you to increase your volume. They can help you to get the equipment you need when you need it, and help you to make changes that are cost effective for your business.

When you are ready to add a beverage carbonator to your process, talk with an expert who can help you ensure your entire process works together to the best benefit of your business, your product, and the flavor of your beer.