Pumps are used in many different industries and come in a range of sizes from the massive industrial pumps used in municipal water and waste systems to small pumps used in the aerospace and medical device industries.

No matter what size of pump in the operation, replacement parts will become a necessity at some time. Finding a machining company offering pump component machining will be a necessity when this happens, and there will be several factors to consider in making your selection.

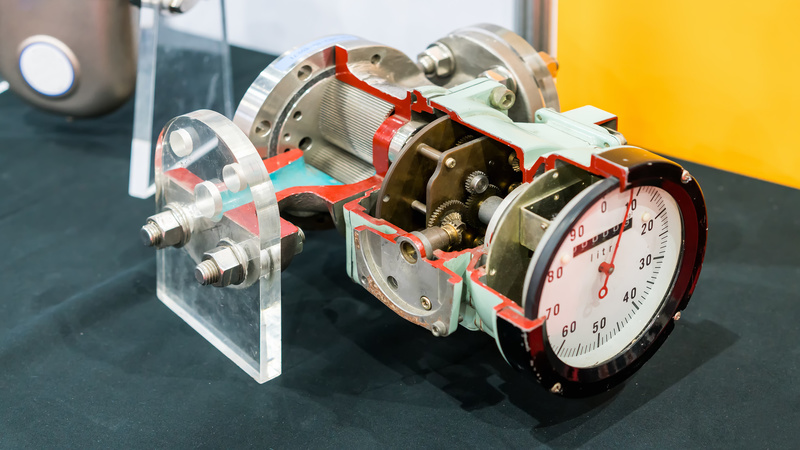

Retrofit Parts

In many situations, the pump component machining requirements may not be in designing a new type of pump or creating a modification to an existing component during the design or prototype testing phase.

It may, in fact, include machining a replacement part or a retrofit part because the pump is obsolete and parts are no longer available from the pump manufacturer. With the high cost of completely replacing the pump, it makes sense to turn to a company with the capacity to re-engineer the part and complete production of a new replacement component.

Smaller and Smaller

In a wide range of industrial and commercial applications from pumps used in aerospace to pumps used in medical equipment, the demand for miniaturized versions of components is always a challenge. Smaller and more durable is always the demand in these types of applications.

Companies that specialize in pump component machining for these types of sectors will have the latest in equipment and technology to be able to assist in the design and production of these smaller and smaller components.

Often with this smaller size and the more complicated shapes and configurations, the use of CNC Swiss turning machines will be a critical factor. These machines are able to accurately and precisely reproduce components down to 0.125 inches, with all necessary operations completed on one machine.

This not only saves time, but it also reduces concerns with quality control or differences between equipment. With the most advanced of these systems, drilling, milling and threading can all be completed on the same machine and at the same time, which is essential for large run production as well as quality control throughout the operations.

With pump components in any field, tight tolerances and precision operations time and time again will be a critical factor. Companies that have this capability can produce high-volume orders within the required lead time, and they can also be instrumental in developing prototype components for these same industries.