Steel plate is difficult to work with unless the metal machining and fabrication service have the right equipment. By definition, steel plate is much thicker than steel sheet metal, which means it requires equipment that is able to effectively pass through the thicker sheet metal without any resulting burrs, deformation of the metal, or issues with high heat levels at the location of the cut.

Any of these types of issues can result in changes in the internal and external properties of the steel, which may require an additional process. Deburring and grinding may correct the problem of uneven cut edges, but they can also decrease the precision of the cut while also increasing the overall cost of producing the part.

Waterjet Cutting

To avoid the issues mentioned above in steel plate cutting, waterjet, plasma, and laser cutting are common options. There are differences in the process, which can make a difference in the best choice for an application.

Waterjet cutting uses high pressure water mixed with abrasives. This is a highly accurate cutting process and can be used with complex shapes, including cuts within shapes. Edges are smooth and precise.

Plasma Cutting

Plasma cutting is typically reserved for thick sheet metal, with thinner metals often resulting in less even edges. Plasma cutting is not as frequently used as in the past, with improvements in laser cutter offering a more versatile solution.

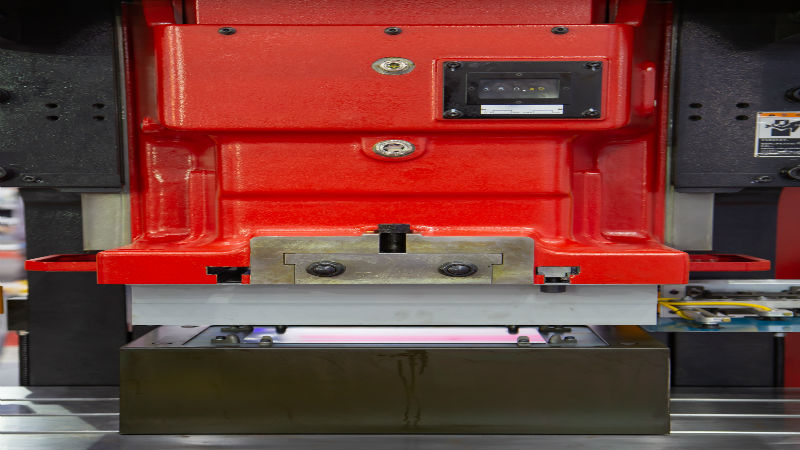

Laser Cutting

Laser steel plate cutting is ideal for even the most complex shapes. It is fast, efficient, and directs a very thin laser at the surface to literally burn through the plate in a smooth, even line.